What is a Diaphragm Filter Press?

Diaphragm Filter Press is a highly efficient and energy-efficient solid-liquid separation device, a special type of filter press. Its key improvement over traditional chamber filter presses lies in the introduction of flexible diaphragm filter plates that can be filled with air or water.

The following are the main features and operating principles of a Diaphragm Filter Press.

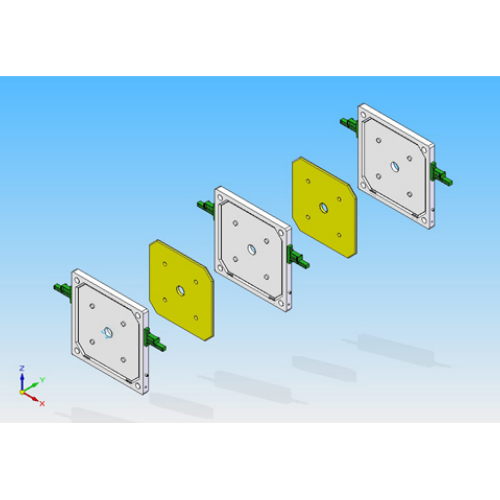

1. Core Structure.

Filter Plates: Typically composed of alternating membrane and standard filter plates.

Diaphragms: This is a key component. The diaphragms are typically a layer of strong, flexible, pressure-resistant, and corrosion-resistant elastic material covering the surface of the membrane filter plates. The diaphragms and the filter plates form a sealed cavity.

Filter Cloths: Covering both sides of the filter plates, they form the filter chamber, trapping solid particles.

Hydraulic System: Compresses all filter plates together to form a sealed filter chamber.

Feed System: Pumps the suspension into the filter chamber.

Pressure Medium System: Injects high-pressure fluid into the cavity behind the diaphragms, causing them to swell.

Drainage System: The filtrate is discharged through the filter cloth, while the filter cake remains in the chamber.

2. Working Principle.

Feed Filtration Stage: Similar to a conventional filter press.

The slurry is pumped into the filter chamber under pump pressure. Solid particles are trapped by the filter cloth, forming a preliminary filter cake. The filtrate is then ejected through the filter cloth.

Diaphragm Pressing Stage (Core Advantage): This is the most critical step unique to membrane filter presses. After the feed is filtered and the filter chamber is filled with the preliminary filter cake, high-pressure fluid is injected into the cavity behind the diaphragm. Under pressure, the diaphragm bulges toward the filter cake. The expanding diaphragm exerts a uniform, powerful secondary mechanical pressure on the filter cake. This strong pressure further compresses the filter cake, squeezing out the capillary water and bound water contained within, significantly reducing its moisture content.

Air Drying Stage: After pressing, compressed air is sometimes introduced through the filter cake to further displace and remove any residual moisture, further reducing its moisture content. During the discharge phase, the diaphragm pressure is released, the filter plates are loosened, and the plates are pulled apart, allowing them to fall away under the influence of gravity or auxiliary devices.

3. Key Advantages:

Low cake moisture content: This is the most significant advantage. The powerful diaphragm pressure significantly reduces the final moisture content of the filter cake, significantly reducing subsequent drying costs.

High filtration efficiency: The pressing process significantly shortens the filtration cycle and improves the equipment's processing capacity.

Excellent washing effect: The pressed filter cake has a denser and more uniform structure. The washing liquid penetrates more evenly, resulting in higher washing efficiency.

High degree of automation: The entire process can be easily automated.

Diaphragm Filter Press uses an expandable elastic diaphragm to apply a powerful secondary mechanical pressure to the filter cake after conventional filtration, significantly reducing the filter cake moisture content, improving filtration efficiency, and reducing energy consumption. It is one of the preferred equipment in modern industry for processing difficult-to-filter materials, achieving low cake moisture content, and achieving high-efficiency solid-liquid separation. It is particularly widely used in environmentally friendly sludge dewatering and mineral processing.