Pressing for Efficiency: A Kitchen Waste Solution in Chile

In the kitchen waste collection and treatment industry, high moisture content has always been a core problem plaguing businesses. It not only increases transportation costs but also affects the efficiency of subsequent composting or resource recovery processes. A client in Chile faced precisely this challenge: they needed to process 1 ton of kitchen waste daily, but the high moisture content led to poor direct composting results and low manual handling efficiency. The client's goal was clear – to find a complete organic waste treatment process line achieving efficient dewatering, automated conveying, and direct integration with a mechanical composter.

What Was the Problem?

The client's original kitchen waste treatment process was laborious and inefficient: waste from 120-liter bins was first dumped onto a sorting table, then manually pushed or carried into the processing equipment. This method was not only inefficient but also failed to effectively control the moisture content, resulting in slow composting and unstable output quality. Furthermore, the client was unsure about the optimal stage to add sawdust and fermentation agents to improve the composting process. The core requirements included:

- Reducing the moisture content of the waste: Ensuring the dewatered material could be fed directly into the mechanical composter.

- Automating the process: Reducing manual intervention and improving the efficiency of processing 1 ton of waste per day.

- Designing a complete process line: Needing equipment covering crushing, dewatering, conveying, and subsequent treatment to ensure a seamless workflow.

How Did We Solve It?

How Did We Solve It?

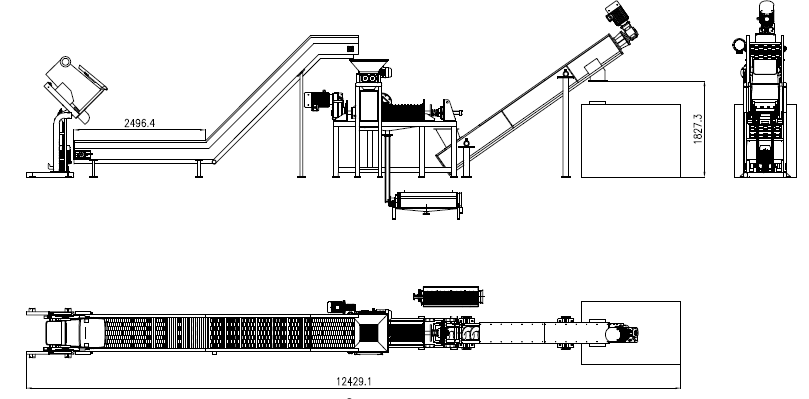

Addressing the client's needs, we tailored an efficient and practical organic waste treatment solution. Centered around a combined crushing and dewatering machine, and integrated with conveying and micro-screening equipment, it achieves one-stop processing from waste to compost-ready material. Key features of the solution include:

- Combined Crushing & Dewatering Machine: Crushes the sorted organic waste and performs dewatering, significantly reducing moisture content. The screw back-pressure system offers pneumatic or hydraulic drive options; if the client's site has an air supply, we recommend the more energy-efficient and easier-to-maintain pneumatic system. The discharge outlet height of the dewatering press can be customized to the client's requirements, ensuring perfect connection with downstream equipment.

- Conveyor: Automatically transports the dewatered material from the press outlet to the inlet of the mechanical composter. The height is adjustable from 250mm to 2500mm, offering flexibility to adapt to various site layouts.

- Rotary Drum Screen**:** Installed at the rear of the dewatering press discharge outlet, it further screens out impurities, improving material purity and laying a solid foundation for composting.

- Optimized Operational Process: The entire workflow—from bin lifting, manual sorting, crushing, and dewatering to automated conveying—is efficient and continuous. Regarding the client's uncertainty about adding sawdust and fermentation agents, we recommend adding them after dewatering and before conveying to ensure uniform mixing.

The client planned to purchase our combined crushing and dewatering machine first, sourcing other equipment locally. We provided comprehensive technical guidance throughout to ensure equipment compatibility and operational ease.

What Was the Client's Feedback?

What Was the Client's Feedback?

After implementation, the client praised the results: "This combined crushing and dewatering machine not only solved the persistent problem of high moisture content but also made the entire process much more efficient and effortless. The dewatered material goes directly into the composter, significantly improving compost quality. The pneumatic system runs stably, and the customized discharge height perfectly matched our site requirements."