How JX Filtration Delivers Custom Drum Screen Success for Guatemala

In the demanding world of industrial filtration, off-the-shelf solutions often fall short. Specific processes, legacy equipment, and unique space constraints require a partner who doesn’t just sell products but engineers solutions. This was precisely the challenge presented by a leading engineering company in Guatemala.

The Problem: Replacing Aging Equipment with Precision Customization

The client approached us with a critical need: to replace worn-out drum screens (also known as sieve tubes or screen cylinders) for their operations. The challenge was multi-faceted:

- Non-Standard Sizes: The existing equipment had specific dimensions that were not readily available in standard market catalogs.

- Complex Segmentation: The drum screens needed to be built in multiple sections (3 or 6) for easier installation, maintenance, or to fit specific machinery designs.

- Detailed & Varied Specifications: Each required screen had unique parameters—different internal diameters, lengths, segmentation counts, and even varied micron precision (0.35mm and 0.50mm) within a single unit.

Simply put, they needed a perfect fit, not just a close approximation. They provided us with the essential foundation: hand-drawn sketches and detailed measurement photos of their current setup and requirements.

Our Solution: From Sketch to Shipment, A Fully Customized Workflow

At JX Filtration, we thrive on such customized projects. Our core strength lies in transforming initial concepts and client-provided data into high-performance, manufactured reality. Here’s how we solved the Guatemalan engineer’s puzzle:

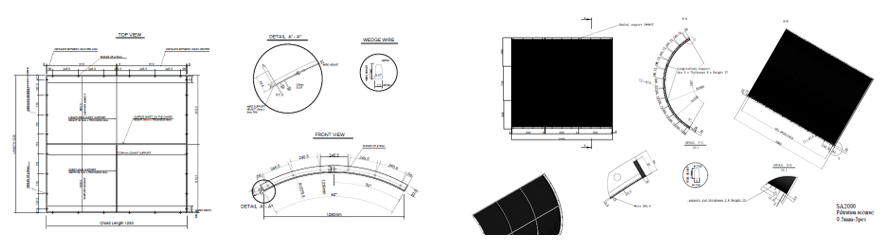

- Collaborative Design & Drawing Approval: We didn’t just take the sketch and proceed. Our engineering team used the client's input to create detailed, professional technical drawings. These drawings specified everything: the segmentation design (built in 3 sections for the SA2000 model, in 6 sections for the IPG and MT models), exact dimensions (Ø2000x2000mm, Ø2500x1225mm), material grades (SS 304L for both wedge wire screen and structure), and the precise slot accuracies (0.5mm, or the mix of 0.35mm/0.50mm). These drawings were sent to the client for full review and confirmation, ensuring 100% alignment with their expectations before any production began.

- Precision Manufacturing: Upon receiving the client's official order and drawing approval, our workshop commenced production. Using high-quality SS 304L stainless steel, we meticulously fabricated the wedge wire panels and robust supporting structures. The key feature—manufacturing the drum screen as pre-assembled sections—was executed with precision to ensure easy on-site assembly and a perfect cylindrical form.

- Seamless Delivery (CIF): After rigorous quality checks, we handled all logistics up to the designated port in Guatemala under CIF terms, ensuring a smooth and worry-free delivery process for our client.

The Result: Satisfaction, Trust, and Repeat Orders

The successful completion and deployment of the first custom drum screen laid the foundation for a strong partnership. The client was thoroughly satisfied with the perfect fit, build quality, and performance of the initial solution.

This satisfaction translated directly into continued trust. The client proceeded to order two additional custom drum screens with different specifications, confident in our ability to deliver tailored precision again.

Contact JX Filtration today. Let’s discuss how we can engineer the perfect custom screen solution for you.