Cartridge Filter Housing Manual

Table of Contents

Manual Overview

Cartridge Filter Operation Instructions

1. Description

The cartridge filter is an innovative filtration system where the inner PEPA sintered filter element performs the filtration process. Liquid flows in through the inlet, undergoes filtration via the filter element, and exits, leaving impurities trapped outside the element.

The cartridge filter is crafted using ultra-high molecular weight polyethylene powder sintering. It is typically used for intermediate or precision filtering. This filter element has high precision, resistance to high temperatures and corrosion, and exceptional mechanical strength.

Application: pharmaceuticals, seawater treatment, food processing, biotechnology, chemicals, petrochemicals, metallurgy, and gas purification.

2. Installation

Inspecting Components

2.1 Please ensure that all necessary components for installing the filtration system are present:

- Main body of Cartridge Filter

- O-ring seals

- Filter element

- One pressure gauge and one exhaust valve

2.2 Examine the O-ring seals and the O-ring grooves on the filtration machine. If any O-ring seals are deformed, exhibit scratches or fractures, or if there are issues with the juncture of the O-ring seals, please replace them with new components.

When commencing the installation, please follow these steps:

- Position the cartridge filter at the designated filtering station and secure it after connecting the inlet and outlet flanges or threads. Plug the exhaust port or install an exhaust valve if applicable.

- Tighten multiple internal filter element onto the mounting plate, and then press down the upper positioning plate.

- Insert the O-ring seal into the O-ring groove, ensuring it remains untwisted or deformed. With one hand on the upper cover handle, slowly lower the upper cover using the top lever wheel until it gently rests on the O-ring seal.

- Align the upper cover and simultaneously tighten the two diagonal bolts, followed by the remaining bolts.

- Close the exhaust valve located on top of the cartridge filter.

- Verify the firmness of all connected pipelines and ensure that the operating pressure remains within the allowed range.

- Gradually open the inlet valve to allow the liquid to flow in slowly, filling the vessel. Then, observe for any leaks in the equipment as a whole. If no leaks are detected, filtration can commence."

3. Daily Usage and Maintenance

3.1 Daily Use

Regularly check the pressure at the inlet and outlet of the filtration system while it's in operation. When the pressure difference between the two points becomes more than 0.15 to 0.2 MPa and the flow decreases noticeably, clean or replace the filter elements promptly. This prevents filter elements damage due to excessive pressure. Also, keep the operating pressure below 0.4 MPa for the best filtration efficiency.

3.2 Opening the Filter Cover Safely

Important: Do not open the filter cover when there's pressure inside. This could lead to liquid spraying out and causing harm or spills.

To open the cover safely:

- Close the input valve and, if there's pressure at the outlet, close the output valve.

- Ensure the exhaust valve's connected pipe is in a safe area. Open the exhaust valve to prevent harm.

- Check the pressure gauge to ensure the pressure is 0, indicating separation from the pipeline.

- If there's a drain valve, ensure the drained liquid goes to a designated place. Open the drain valve and close it after the liquid drains.

- Loosen the upper cover bolts and lift the cover.

3.3 Replacing Filter elements

- Open the filter housing cover.

- Lift the cover's lever arm, loosen the bolts securing the filter element mounting plate, and carefully remove the filter element.

- Insert the new filter element, cover it with the filter bag cap, and tighten the screws.

3.4 Checking Filtration Quality:

- When the liquid input pressure is stable, the quality of filtration is related to the pressure difference inside and outside the filter element. If the input pressure is too high, it means the filter might be blocked, slowing down the process. So, it's a good idea to regularly check the input pressure while the filter is working. Use the pressure gauge to decide when to clean or change the filter element. This helps prevent the filter element from breaking and keeps filtration effective.

- If the input pressure suddenly drops, stop and check for leaks.

3.5 Pressurized Discharge of Residual Liquid

When filtering thick liquids, you can speed up draining the leftover liquid using the exhaust valve with compressed air. This shortens the wait time.

Here's how it works:

- Close the input valve.

- Open the air intake valve.

- Use compressed air to push out the remaining liquid.

- Check the pressure gauge to match the air pressure. Make sure no liquid is coming out.

- Close the air intake valve.

- Open the exhaust valve slowly. Liquid might come out, so guide it safely.

- After releasing all the compressed air, close the exhaust valve. Now, you can open the filter cover.

3.6 Cleaning the Filter

If you're filtering the same liquid, no cleaning is needed. But if you switch liquids, clean the machine before using.

3.7.Caring for and Changing O-Ring Seal

- Care: When using, put the O-ring seal correctly in the groove to prevent squishing. When not filtering, remove and clean the O-ring seal. Otherwise, leftover liquid could harden and affect the seal.

- Change: If the O-ring seal is old or broken, replace it. Use the same model when replacing.

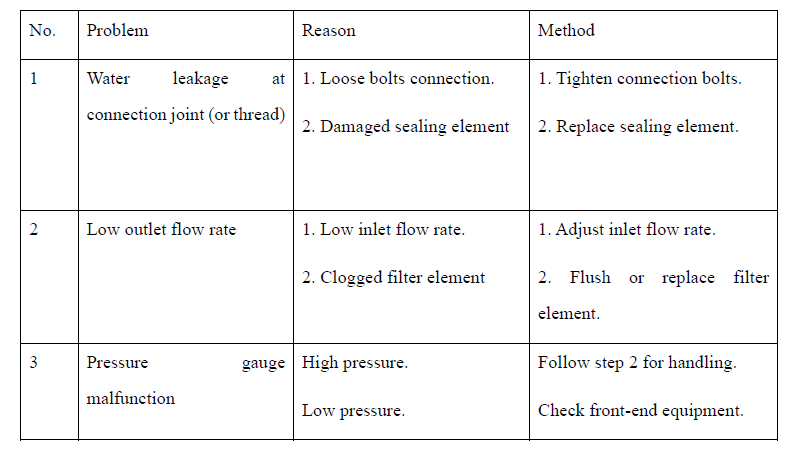

4. Possible Malfunctions and Remedies

Important Note:

Important Note:

Do not use this equipment above its designed pressure limit. It could result in equipment damage and safety issues. Our company is not responsible for any consequences caused by such actions.

Appendix:

Usage and Maintenance Instructions for Ultra-High Molecular Weight Polyethylene Sintered Filter Elements

- Filter Element Material

- Ultra-high molecular weight polyethylene sintered filter element, resistant to acids, alkalis, and common solvents.

- PE Operating Temperature

- PE (white) below 80°C, PA (gray) below 110°C.

- Usage:

- Visually inspect for defects.

- Clean thoroughly with clean water (or purified water).

- Recommended operating pressure is between 2-3 kg/cm².

- Based on material characteristics, viscosity, impurity content, and particle size distribution, determine the backwash process. Use pure water for backwashing. If water isn't feasible, compressed air can be used, with backwash pressure greater than 4 kg/cm² and less than 6 kg/cm².

- After normal backwashing for a period of time, if the filter element's flow rate decreases and doesn't meet requirements, remove the element. Soak it in acid or alkali solution using the following methods:

- If impurities or solution are alkaline, use diluted hydrochloric acid (below 8%), soak for over 4 hours, then backwash.

- If impurities or solution are acidic, use diluted alkali solution (NaOH or KOH below 8%), soak for over 4 hours, then backwash.

- If unsure about acid, alkaline, or neutral, use the method from (1).

- If, after several cleaning cycles, the flow rate decreases by half, consider replacing the filter element.

This section provides comprehensive documentation for all products in the Cartridge Filter Housing category. Please select a specific product below to view its detailed manual.

Available Products

SS304-Cartridge Filter Housing

SS2205-12+40-Cartridge Filter Housing

3-30“-SS316Cartidge Filter Housing-food grade

SS2205-8+40-Cartridge Filter Housing

SS316-18+40 - Cartridge Filter Housing

SS2507-30+40-Cartridge Filter Housing

PPH-5+30"-Cartidge Filter Housing

SS316-5+40“-Cartidge Filter Housing

SS316-40+40”-Cartridge Filter Housing

SS316-30+40-Cartridge Filter Housing

SS316-8+40-Cartridge Filter Housing

SS316-7+40-Cartidge Filter Housing

SS316-3+40-Cartidge Filter Housing

SS316-5+30-Cartridge Filter Housing

SS304-40+40-Cartridge Filter Housing

SS304-18+40-Cartridge Filter Housing

SS304-18+40 - Cartridge Filter Housing

SS304-40+40 - Cartridge Filter Housing

SS304-12+60-Cartridge Filter Housing

SS304-20+60-Cartridge Filter Housing

SS304-3+30-Cartridge Filter Housing

SS304-540+40-Cartridge Filter Housing

SS304-30+60-Cartridge Filter Housing

SS304-3+40-Cartridge Filter Housing

SS316-10+40-Cartridge Filter Housing

SS316-1+40-Cartidge Filter Housing

SS316-7+30-Cartridge Filter Housing

SS316-5+40-Cartidge Filter Housing

SS316+PTFE-Single core 10 inches-226 interface core filter

Cartridge Filter Housing

SS316-5+40-Cartidge Filter Housing(Clamps)

SS316+PES-226-Cartridge Filter Housing

SS316+PES-30-Cartidge Filter Housing

SS304-10+40-Cartidge Filter Housing

PPH-30-Cartidge Filter Housing

SS304-6+20-Cartridge Filter Housing

SS304-12+40-Cartridge Filter Housing

SS304-11+40-Cartridge Filter Housing

SS304-10+40-Cartridge Filter Housing

SS304-8+40-Cartridge Filter Housing

SS304-50+40-Cartridge Filter Housing

SS304-50+40-Cartidge Filter Housing

SS304-Single core 10 inches-226 interface core filter

3-Core 222 Interface Core Filter

SS316L-3-Core 222 Interface Core Filter

Cartidge Filter Housing-food grade

Cartidge Filter Housing

SS304-1+40-Cartidge Filter Housing

SS304-5+60-Cartidge Filter Housing

SS304-12+40-Cartidge Filter Housing

SS316-40+40-Cartidge Filter Housing

SS304-20+40-Cartidge Filter Housing

SS304-80+40-Cartidge Filter Housing

SS304-25+40-Cartidge Filter Housing

SS316-34+40-Cartidge Filter Housing

SS316-10+40-Cartidge Filter Housing

SS304-16+40-Cartridge Filter Housing

SS2205-540+40-Cartridge Filter Housing

SS304-7+30-Cartridge Filter Housing

Need Help?

If you need additional assistance with any product in this category, please contact our support team.