Pre-coating Vacuum Drum Filter Manual

Table of Contents

Manual Overview

Vacuum Drum Filter Operation Instructions

I. Startup

1. Before starting, carefully check: There should be no foreign objects in the liquid tank, agitator frame, or drum; whether the filter cloth is properly installed; whether the scraper is fixed in the correct position (first adjust to 10mm from the drum surface, and then adjust the gap according to the cake thickness after normal operation). Check whether the reducers are lubricated, whether the motor wiring is correct, and whether the pipeline connections are correct.

2. Start the drum, gradually increasing the speed from low to high, ensuring the rotation direction is correct (viewed from the distribution head, the drum should rotate clockwise).

3. Start the agitator, paying attention to any abnormal noises during operation.

4. Start the vacuum system. (Refer to the vacuum pump manual for maintenance.)

Pre-operation checks:

a) Check whether all components of the vacuum pump are securely fixed.

b) Check whether the vacuum valve connected to the drum equipment is closed.

c) Check whether the circulating water is turned on.

d) Start the motor briefly to check whether the rotation direction is correct.

Startup:

a) Press the pneumatic button to start the vacuum pump.

b) Check whether the vacuum gauge and water temperature are normal and whether there are any abnormal noises during operation.

Shutdown:

Close the vacuum valve of the connected equipment, open the drain valve, and turn off the vacuum pump button.

II. Feeding and Filtration

1. Observe the startup process. Once everything is normal, prepare to feed.

2. Open the feed valve and evenly inject the suspension, maintaining the slurry level so that suspension flows out of the overflow port.

3. Observe the filtration process and make adjustment:

a) Adjust the drum speed to the optimal level based on the filtration rate and production capacity.

b) Adjust the spiral roller speed based on the cake condition to ensure smooth cake discharge.

c) Check the sealing condition of the two misalignment plates (stationary plate and rotating plate). If the sealing is poor, adjust the sealing compression device.

d) For cakes requiring washing, open the washing pipe on the drum and adjust the flow rate to achieve the best washing effect.

III. Shutdown

After the suspension filtration is completed, shut down according to the following steps:

1. Close the suspension feed valve to stop injecting the suspension.

2. Continue operating the drum until the suspension level in the liquid tank is below the lowest point of the drum.

3. After all the cake on the filter cloth is discharged, turn off the vacuum system.

4. Open the flushing valve to clean the drum, liquid tank, and agitator frame, and open the drain valve.

5. Close the flushing valve.

6. Turn off the main motor (drum motor).

IV. Maintenance

Proper maintenance of the filter is crucial for ensuring normal operation and extending the machine's service life. Users should pay attention to the following during operation and maintenance:

1. During the operation of the filter, all transmission components should be regularly lubricated according to the manufacturer's requirements for each reducer. (Replace the lubricating oil every 3-6 months based on actual usage frequency, using No. 320 gear oil)

2. The suspension concentration should be kept as stable as possible to avoid affecting production capacity and filtration quality. If the suspension concentration changes, promptly adjust the drum rotation speed and spiral roller speed to ensure good filtration performance.

3. The fixed misalignment plate has two oil grooves for lubricating the friction surfaces between the two misalignment plates. These grooves are prone to clogging by particles in the filtrate. To prevent wear of the friction surfaces due to solid particle clogging, regularly clean them to keep the lubrication channels clear. Special attention: when cleaning clogged oil grooves, do not loosen the fixing screws between the fixed misalignment plate and the distribution head, or between the rotating misalignment plate and the misalignment shaft, to avoid affecting the sealing effect between the plates.

4. Regularly check the operation of all moving parts. If any jamming, abnormal noise or other phenomena are found, promptly identify the cause and resolve the issue.

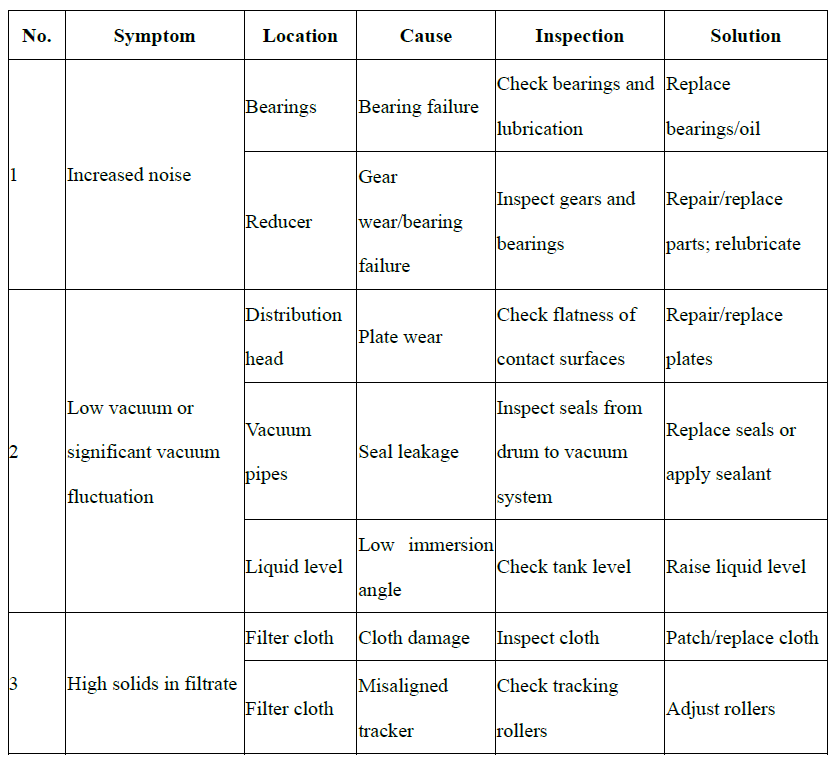

V. Troubleshooting

This section provides comprehensive documentation for all products in the Pre-coating Vacuum Drum Filter category. Please select a specific product below to view its detailed manual.

Available Products

PP-8m²-Pre-coating Vacuum Drum Filter

SS304-8m²-Pre-coating Vacuum Drum Filter

PP-6m²-Pre-coating Vacuum Drum Filter

SS304-6m²-Pre-coating Vacuum Drum Filter

SS316-5m²-Pre-coating Vacuum Drum Filter

SS304-5m²-Pre-coating Vacuum Drum Filter

SS304-30m²-Pre-coating Vacuum Drum Filter

PP-2m²-Pre-coating Vacuum Drum Filter

SS304-2m²-Pre-coating Vacuum Drum Filter

PP-1m²-Pre-coating Vacuum Drum Filter

SS316-1m²-Pre-coating Vacuum Drum Filter

PP-0.5m²-Pre-coating Vacuum Drum Filter

SS304-0.5m²-Pre-coating Vacuum Drum Filter

SS316-30m²-Pre-coating Vacuum Drum Filter

SS316-0.5m²-Pre-coating Vacuum Drum Filter

SS304-1m²-Pre-coating Vacuum Drum Filter

SS316-8m²-Pre-coating Vacuum Drum Filter

SS316-2m²-Pre-coating Vacuum Drum Filter

SS316-6m²-Pre-coating Vacuum Drum Filter

PP-5m²-Pre-coating Vacuum Drum Filter

Need Help?

If you need additional assistance with any product in this category, please contact our support team.