Linear Vibrating Screen Machine Manual

Table of Contents

Manual Overview

1. Product Application and Scope of Use

This product is primarily a seat-type installed multi-layer vibrating screening machine. It can be matched with corresponding screen plates based on the user's mesh size requirements for different materials, achieving simultaneous screening and filtration of multiple specifications of materials in a single pass. The screen changing process is simple, and the equipment is easy to operate, offering a wide range of applications. It is mainly used in industries such as chemical, papermaking, metallurgy, building materials, grain, abrasives, and chemical fertilizers for the screening, grading, and dewatering of granular and powdery materials.

2. Main Structure (See Diagram)

This product mainly consists of: screen box, screen plate, vibration motor, and support device.

a) Box Body: Mainly welded from Q235 mild steel plates, or can be welded from various stainless steel plates as per user requirements.

b) Screen Surface: The screen surface of this machine has two structural forms: stainless steel wedge wire screen plates and metal wire woven mesh. They are fixed using vertical compression and longitudinal tension methods respectively. Screen surface replacement is convenient and quick, with a long service life.

c) Vibration Motor: This equipment uses two horizontal vibration motors to generate the vibration source. Adjusting the eccentric blocks at both ends of the motors allows adaptation to different vibration force requirements.

d) Support Device: The support device consists of a support frame welded from channel steel and support springs. The screen surface inclination angle can be changed by altering the height of the front and rear support legs.

3. Working Principle

Two vibration motors are installed at the lower part of the screen machine, operating synchronously and in reverse rotation during work. The eccentric blocks generate the rated vibration force during rotation. Under the action of this force, the box body supported on four damping springs produces reciprocating linear vibration. When the vertical component (N) of the trough body's vibration acceleration is greater than gravity (G), the material in the trough is thrown up and moves forward in a parabolic trajectory, jumping. Each time the trough vibrates, the material is thrown up once. During the encounter with the screen surface, material smaller than the screen aperture passes through the screen surface, thus achieving the purpose of grading.

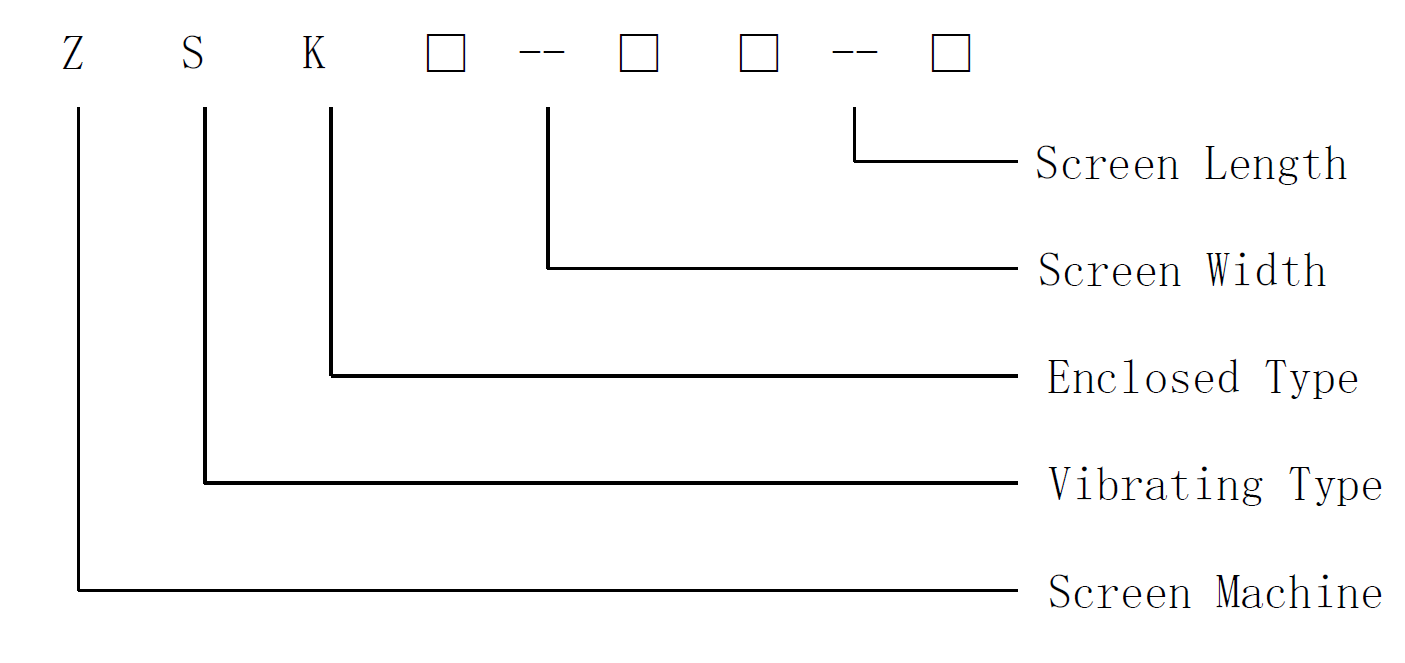

4. Model Specification Description

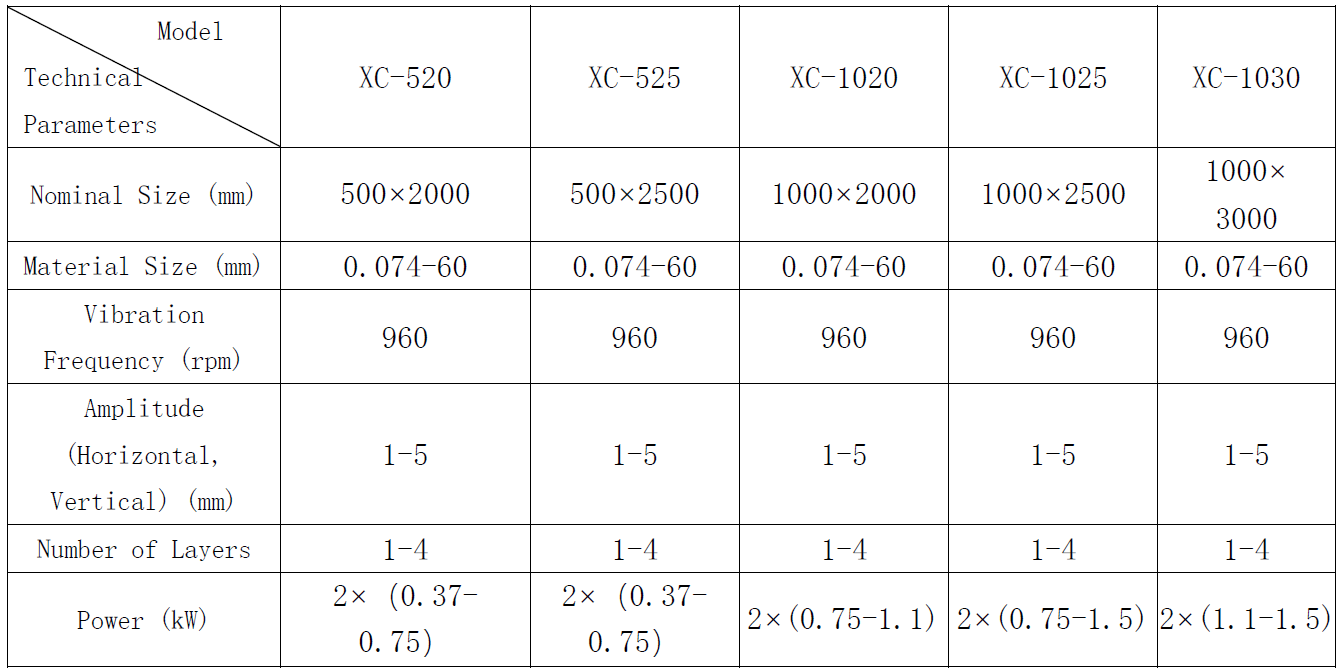

5. Main Technical Parameters

5. Main Technical Parameters

Note: The nominal size can be custom-designed according to user needs.

Note: The nominal size can be custom-designed according to user needs.

6. Installation and Commissioning

a) During equipment installation, find the foundation level, then install the support frame. After adjusting the relative position and preliminary fixing, install the damping springs in sequence. Then, hoist the screen body above the support and slowly lower it onto the damping springs.

b) There should be no fixed objects within 100mm around the linear screen box. If the inlet and outlet need sealed connection, use soft connections, such as industrial canvas. To prevent material from falling and damaging the screen mesh, the vertical drop distance from the feed inlet to the screen surface should not be greater than about 1000mm. To fully utilize the effective screening area of the screen machine, the feeding device should distribute the material evenly across the entire width of the screen's feed inlet. It should not accumulate in a small central area of the inlet.

c) When wiring the vibration motors, ensure the two motors are connected in parallel and rotate in opposite directions.

The power supply cable for the motors should have some slack and be grounded.

The power supply cable for the motors should have some slack and be grounded.

d) After installation is complete, check the tightness of all bolts on the equipment and observe if the screen machine has contact with surrounding objects. Sufficient clearance must be left to eliminate the possibility of collision when starting up and generating vibration.

e) The screen machine should undergo a trial run for two hours. There is a resonance zone of about three seconds during startup and shutdown, where the amplitude is relatively large; this is a normal phenomenon. During operation, there should be no transverse vibration; it should perform linear vibration along the direction of the vibration force. If the linear vibrating screen is installed on a steel structure frame or a floor with insufficient strength, it is prone to produce destructive resonance. Resonance can easily tear the steel plates of the screen machine. Therefore, a solid foundation should be prepared to prevent resonance; otherwise, the equipment must not be put into production.

f) Adjusting the angle of the four sets of eccentric blocks on the two motors can change the magnitude of the vibration force. During adjustment, first remove the protective cover, then loosen the bolts of the inner eccentric blocks. Rotate the eccentric blocks at both ends in the same direction to achieve the required vibration force. Then tighten the eccentric block bolts and install the protective cover. The maximum vibration force occurs when the two eccentric blocks in each set are aligned. The smaller the angle between them, the smaller the vibration force. Remember, the angles of the four sets of eccentric blocks must be consistent.

7. Operation and Maintenance

a) Operators should be familiar with the performance, structural principles, and maintenance checkpoints of each part of this equipment.

b) Perform equipment inspection each shift. Check whether bolts in various parts are loose, and whether the screen surface is loose or damaged. If bolts are loose, tighten them promptly. If the screen surface is damaged, replace it promptly.

c) During operation, strive for uniform and moderate feed rate. Except under special circumstances, strictly avoid stopping the machine with material on it or continuing to feed material after shutdown.

d) The vibration motor is a key component of this equipment. The maintenance and care of the motor should be carried out with reference to the vibration motor operating manual.

This section provides comprehensive documentation for all products in the Linear Vibrating Screen Machine category. Please select a specific product below to view its detailed manual.

Available Products

SS316-1530-1S-Linear Vibrating Screen Machine

SS316-1530-2S-Linear Vibrating Screen Machine

SS304-1030-2S-Linear Vibrating Screen Machine

SS304-1030-3S-Linear Vibrating Screen Machine

SS304-1230-1S-Linear Vibrating Screen Machine

SS304-1230-3S-Linear Vibrating Screen Machine

SS304-820-3S-Linear Vibrating Screen Machine

Need Help?

If you need additional assistance with any product in this category, please contact our support team.