Channel Drum Screens Manual

Table of Contents

Manual Overview

Operation and Maintenance Manual for Rotary Drum Screen

Working Principle

The equipment is installed at a 35° angle from the horizontal plane in the water channel. Wastewater flows into the drum from the inlet end. Water passes through the screen mesh gaps, while solid waste is retained inside the drum. As the drum rotates to its highest point, the waste is removed from the mesh by water flushing and the scum baffle, falling into the screw conveyor hopper.

During conveying, the material is dewatered due to the variable pitch design, and further squeezed dry in the compression zone at the top. The squeezed water is returned to the channel, while the collected waste is discharged into a container or subsequent processing equipment.

Installation Instructions

- The rotary drum screen should be placed stably on the working platform.

- The machine’s base must be fixed to the ground with expansion bolts. Trial operation can only begin once there is no noticeable vibration.

- When operating in conjunction with other equipment, ensure the discharge hopper of the conveyor aligns properly with the receiving device.

H1: Channel Depth H2: Discharge Height H: Total Equipment Height

Operation Instructions

- Before use, fill the gearbox with mechanical oil up to 1/2 of the sight glass (refer to the gearbox manual).

- After connecting the power supply, jog the start button to check the screw rotation direction. The screw must always rotate toward the material outlet.

- During operation, ensure that no hard objects enter the machine. If any abnormal sound or situation occurs, stop the equipment immediately and eliminate the fault before restarting.

- Always disconnect and lock out the main power supply before any maintenance or inspection.

- Do not touch the protective screen mesh while the machine is running.

- If the machine has been idle for over 24 hours, an operator must be present during restart to monitor operation.

Maintenance and Care

- This equipment is semi-automatic and must be operated under supervision.

- Regularly inspect the nylon liners for wear (visual check). Replacement should be done under professional guidance. Also check the screen mesh and drum for damage or clogging.

- Regularly inspect the screw for wear. Up to 10% of the original screw thickness may be worn off before replacement is needed.

- Perform a comprehensive cleaning and maintenance every two months.

- In case of malfunction, stop operation immediately and contact the manufacturer for service.

- For long-term storage:

- Clean the screw blades and mesh thoroughly using a high-pressure water jet.

- Wear protective clothing during cleaning.

- Routine inspection:

- Check bearings, foundation bolts, and other wear parts.

- Tighten or replace if loose, worn, or displaced.

- If the anti-corrosion coating is damaged, remove rust and repaint promptly.

- Annual maintenance:

- Clean the entire machine thoroughly.

- Check the clearance between screw blades (should be 2–3 mm). Replace the lower bushing if out of tolerance.

- After every 5,000 operating hours, replace the gearbox oil.

- Before Disassembly:

- Run the machine to discharge all material, then flush with water until clean.

- Do not use hands or tools to reach inside the conveying tube.

- To prevent contamination, clean the unit with a steam jet, drain the gearbox oil, and attach a weatherproof “Oil Drained” tag.

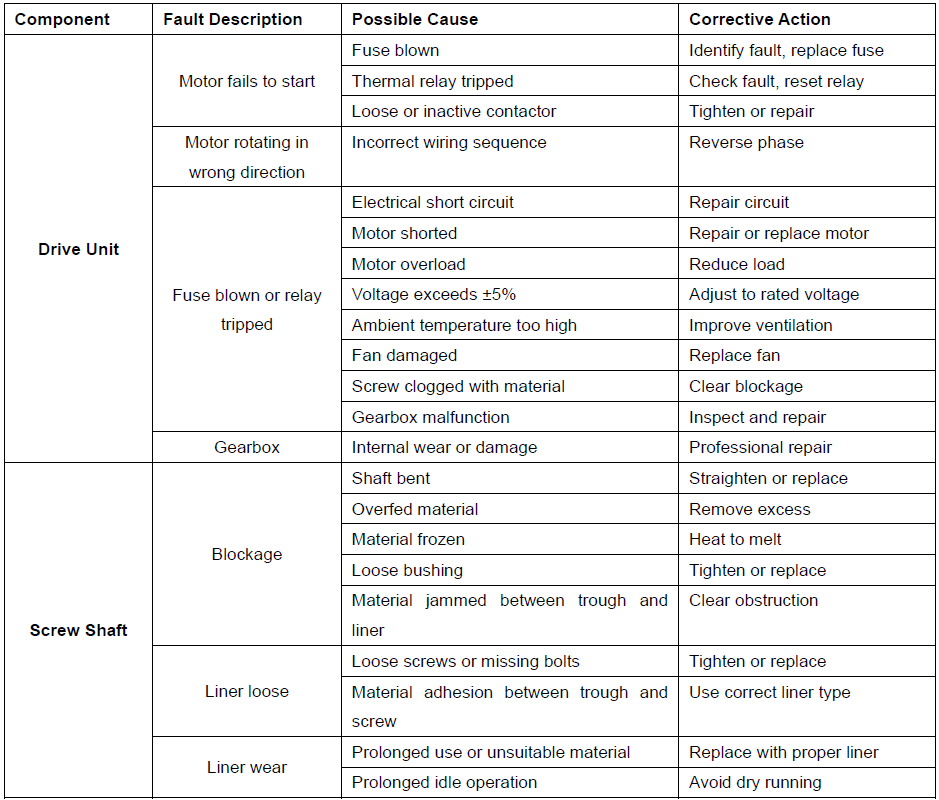

Repair and Troubleshooting

Repair and servicing must be carried out only by trained professionals with the necessary technical expertise.

This section provides comprehensive documentation for all products in the Channel Drum Screens category. Please select a specific product below to view its detailed manual.

Available Products

SS316-Z1600-Channel Microfilter

SS304-Z1600-Channel Microfilter

SS316-Z2000-Channel Microfilter

SS304-Z2000-Channel Microfilter

SS316-Z1400-Channel Microfilter

SS304-Z1400-Channel Microfilter

SS316-Z400-Channel Drum Screens( enclosed)

SS316-Z300-Channel Drum Screens

SS304-Z400-Channel Drum Screens( enclosed)

SS304-Z300-Channel Drum Screens

SS316-Z600-Channel Drum Screens

SS316-Z800-Channel Drum Screens

SS304-Z800-Channel Drum Screens

SS316-Z400-Channel Drum Screens

SS304-Z400-Channel Drum Screens

SS304-Z600-Channel Drum Screens

SS316-Z1200-Channel Microfilter

SS316-Z1000-Channel Microfilter

SS316-Z900-Channel Microfilter

SS304-Z1000-Channel Microfilter

SS304-Z1200-Channel Microfilter

SS304-Z900-Channel Drum Screens

Need Help?

If you need additional assistance with any product in this category, please contact our support team.