Sand Filter Manual

Table of Contents

Manual Overview

Sand Filter Operation Instructions

I. Sand Filter

1.1 Description of Sand Filter

Sand filter is controlled by PLC microcomputer, with electric butterfly valves for valves. The sand filter adopts stainless steel 304 wound wire tube, low resistance, high flux, and is filled with high-quality quartz sand inside. Its main function is to intercept and adsorb sediment, colloids, metal ions, and organic matter through the filter media. It is commonly used for purifying water and wastewater treatment due to its pollution-free nature, low cost, and low operating costs, making it widely applicable. During initial use, reverse flushing should be conducted for several minutes until wastewater is discharged to normal operation.

Filtration rate: V = 815m/h, Vmax = 15m/h. Operating temperature: 540°C.

Operating pressure: 0.3--0.4MPa. (Inlet head 30-40 meters).

1.2 Precautions for Filling Filter Media in Sand Filters

a. Firstly, determine the orientation of the sand filter. The filter must be placed steadily on a platform capable of bearing 20 tons. Then, open the DN400 manhole and check for any foreign objects inside. Also, ensure the stainless steel wire-wound filter at the bottom is not loose. (Refer to the pipeline valve direction shown in the diagram and the pipeline brackets on the body to confirm the orientation of the filter. Before filling the filter media, it is crucial to establish the orientation. Otherwise, moving the filter after filling the media will be difficult.)

b. Fill the tank with quartz sand.

c. Close the manhole cover and tighten the screws of the manhole cover

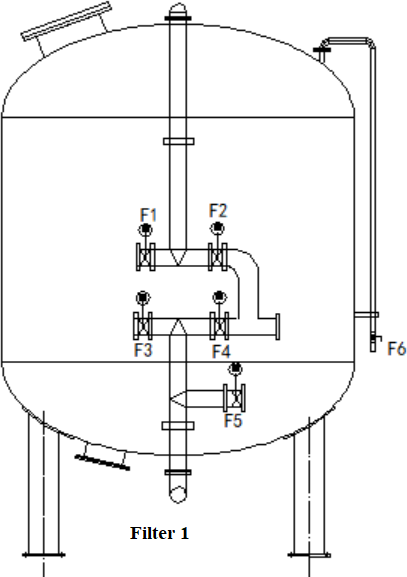

1.3 Schematic Diagram of Pipeline Valve Connections for Sand Filter Body

F1: Inlet valve 1 (also serves as forward wash inlet valve) F2: Backwash valve 1

F3: Backwash inlet valve 1

F4: Forward wash outlet valve 1 F5: Outlet valve 1

F6: Manual air release valve

II. Sand Filter

1.1 Description of Activated carbon filter

Activated carbon filter, constructed entirely from carbon steel with internal rubber lining for corrosion protection or stainless steel, utilizes stainless steel 304 wrapped wire mesh for high flow and low resistance. Activated carbon consists of very fine charcoal particles with numerous micro-pores, often referred to as capillary pores. These capillary pores possess strong adsorption capabilities due to the large surface area of the carbon particles, facilitating thorough contact with impurities in water. These impurities can be adsorbed into the micro-pores, effectively removing colloids and other contaminants from the water. Activated carbon can also adsorb chlorine ions, ozone, and organic compounds present in water, and notably absorbs colorants. Widely used in water purification and wastewater treatment due to its non-polluting nature, low cost, and minimal operational expenses, it requires initial flushing both forward and backwashing for a few minutes to discharge wastewater before normal operation can commence.

Filtration rate: V = 512m/h, Vmax = 15m/h. Operating temperature: 540°C.

Operating pressure: 0.3--0.45Mpa

1.2 Precautions for Filling Filter Media of Activated carbon filter

a. Firstly, determine the orientation of the activated carbon filter. The filter must be placed steadily on a platform capable of bearing 20 tons. Then, open the DN400 manhole and check for any foreign objects inside. Also, ensure the stainless steel wire-wound filter at the bottom is not loose. (Refer to the pipeline valve direction shown in the diagram and the pipeline brackets on the body to confirm the orientation of the filter. Before filling the filter media, it is crucial to establish the orientation. Otherwise, moving the filter after filling the media will be difficult.)

b. Fill the tank with activated carbon.

c. Close the manhole cover and tighten the screws of the manhole cover

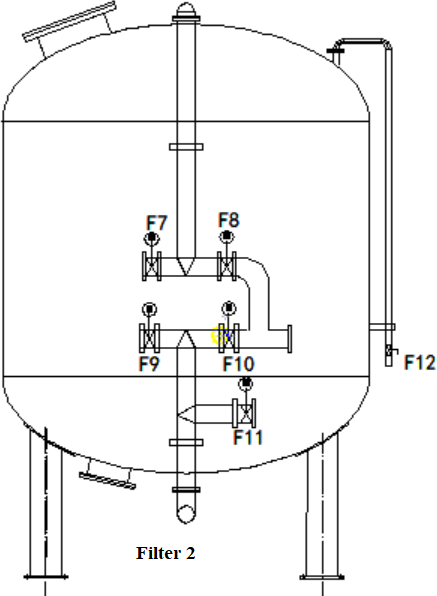

1.3 Schematic Diagram of Pipeline Valve Connections for Sand Filter Body

F7: Inlet valve 2 (also serves as forward wash inlet valve) F8: Backwash valve 2

F9: Backwash inlet valve 2

F10: Forward wash outlet valve 2 F11: Outlet valve 2

F12: Manual air release valve

III. Commissioning

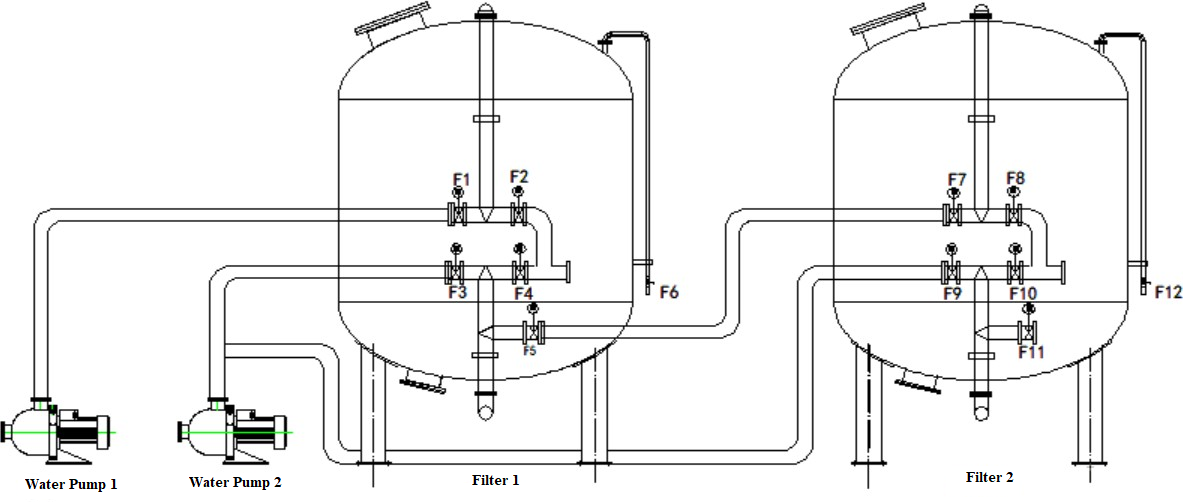

1.1 Explanation of Process Flow Diagram

Water Pump 1: Feed

Water Pump #1 Water Pump 2

Backwash Pump #1 Filter 1: Sand Filter

Filter 2: Activated Carbon Filter

1.2 Backwashing and Forward Washing Instructions

1# Quartz Sand Filter and 1# Activated Carbon Filter are grouped together. Manual operation involves first performing manual cleaning. Open backwash valve 1, backwash outlet valve 1, then start backwash pump 1# for approximately 5 minutes for the #1 sand filter. Afterwards, close backwash pump 1#, shut off backwash valve 1, backwash outlet valve 1, open inlet valve 1, forward wash valve 1, and start feed water pump 1# for approximately 2-3 minutes as needed. After the time is up, open outlet valve 1, shut off forward wash valve 1, and allow #1 sand filter to produce water. Production time for #1 sand filter can be set between 5-8 hours as needed. Cleaning for #1 activated carbon filter follows a similar process. First, open backwash valve 2, backwash outlet valve 2, then start backwash pump 1# for approximately 5 minutes as needed for the #1 carbon filter. Afterwards, close backwash pump 1#, shut off backwash valve 2 and backwash outlet valve 2, open inlet valve 2, forward wash valve 2, and start feed water pump 1# for approximately 2-3 minutes as needed. After the time is up, open outlet valve 2, shut off forward wash valve 2, and allow production of water. Note that the #1 carbon filter can only be forward washed when the #1 sand filter is producing water. After water production, manually close all valves for #1 sand filter and feed water pump 1# before beginning backwash for #1 carbon filter. Open backwash valve 2, backwash outlet valve 2, and start backwash pump 1#. Once completed, proceed with forward wash for #1 carbon filter by opening inlet valve 2, forward wash valve 2, and start feed water pump 1#. After cleaning, water production can commence by opening inlet valve 1, outlet valve 1, inlet valve 2, outlet valve 2, and starting feed water pump 1#.

Filter #2 Quartz Sand Filter and Filter #2 Activated Carbon Filter operate in the same manner. Automatic operation:

First, set various parameters on the touchscreen:

- Set backwash pressure for #1 quartz sand filter (approximately 100kPa)

- Set backwash pressure for #1 activated carbon filter (approximately 100kPa)

- Set water production time for #1 filter between 5-8 hours as needed

- Set backwash time for #1 quartz sand filter between 3-5 minutes as needed

- Set forward wash time for #1 quartz sand filter between 2-3 minutes as needed

- Set backwash time for #1 activated carbon filter between 3-5 minutes as needed

- Set forward wash time for #1 activated carbon filter between 2-3 minutes as needed Repeat the same settings for #2 filters.

After setting parameters, turn the touchscreen knob to "Auto" mode. Use remote signals for control; filters will automatically backwash based on set pressure. Once the pressure reaches the set value, follow the time set on the touchscreen for the next operation step. This process cycles through backwashing, forward washing, and water production. Ensure all system pipelines are clear before and during pump operation to prevent damage to pumps or pipelines.

IV. Routine Maintenance

1. Quartz sand is typically replaced every 1-2 years, but the replacement period can be extended based on actual conditions.

2. Activated carbon is generally replaced annually, but the replacement period can be extended based on actual conditions.

This section provides comprehensive documentation for all products in the Sand Filter category. Please select a specific product below to view its detailed manual.

Available Products

SS316-3200-Sand Filter( Electric Valve)

SS304-2500-Sand Filter( Manual Valve)

Carbon Steel-2500-Sand Filter( Manual Valve)

Carbon Steel-2500-Sand Filter( Electric Valve)

SS304-3200-Sand Filter( Manual Valve)

SS304-3200-Sand Filter( Electric Valve)

SS304-3200-Sand Filter( Without valve)

Carbon Steel-3200-Sand Filter( Without valve)

Carbon Steel-3200-Sand Filter( Electric Valve)

SS304-3000-Sand Filter(Without valve)

SS304-3000-Sand Filter(Manual Valve)

SS304-3000-Sand Filter(Electric Valve)

Carbon Steel-3000-Sand Filter(Electric Valve)

Carbon Steel-3000-Sand Filter(Manual Valve)

SS304-2800-Sand Filter(Electric Valve)

SS304-2800-Sand Filter(Without valve)

SS304-2800-Sand Filter(Manual Valve)

Carbon Steel-2800-Sand Filter(Manual Valve)

Carbon Steel-2200-Sand Filter(Manual Valve)

SS304-2200-Sand Filter(Manual Valve)

SS304-2000-Sand Filter(Electric Valve)-Copy

Carbon Steel-2000-Sand Filter(Electric Valve)

Carbon Steel-2000-Sand Filter(Manual Valve)

SS304-2000-Sand Filter(Manual Valve)

SS304-2000-Sand Filter(Without valve)

SS304-1500-Sand Filter( Electric Valve)

Carbon Steel-1500-Sand Filter( Electric Valve)

SS304-1500-Sand Filter(Manual Valve)

Carbon Steel-1500-Sand Filter(Manual Valve)

SS304-1200-Sand Filter(Manual Valve)

Carbon Steel-1200-Sand Filter(Manual Valve)

Carbon Steel-1000-Sand Filter(Manual Valve)

SS304-1000-Sand Filter(Manual Valve)

Carbon Steel-1000- Sand Filter(Automatic Valve)

SS304-1000-Sand Filter(Without valve)

Carbon Steel-900-Sand Filter(Without valve)

Carbon Steel-900-Sand Filter(Hand Valve)

SS304-800-Sand Filter( Electric Valve)

SS304-800-Sand Filter-(Without valve)

Carbon Steel-900-Claw-type Sand Filter

Carbon Steel-800-Sand Filter( Electric Valve)

2200-Sand Filter( control system and pipeline valves)-CS

SS304-2500-Sand Filter( control system and pipeline valves)

SS304-2200-Sand Filter( control system and pipeline valves)

SS304-2200-Sand Filter(Without valve)

SS304-1600-Sand Filter(Electric Valve)

Carbon Steel-1200-Sand Filter(Electric Valve)

SS304-1200-Sand Filter(Electric Valve)

SS316-800-Sand Filter

SS316-2500-Sand Filter

SS304-2500-Sand Filter

SS316-1200-Sand Filter(No valve claw type)

SS304-1200-Sand Filter(No valve claw type)

Carbon Steel-800-Sand Filter(Hand Valve)

SS304-800-Sand Filter(Hand Valve)

SS304-900-Sand Filter(Hand Valve)

SS304-900-Sand Filter

SS304-900-Claw-type Sand Filter

SS304-1000-Claw-type Sand Filter

Carbon Steel-1800+6"-Sand Filter

Carbon Steel-2200-Sand Filter

Carbon Steel-1800-Sand Filter

Carbon Steel-1500-Sand Filter(without nozzle)

Carbon Steel-1200-Sand Filter

Carbon Steel-1000-Sand Filter-Carbon Steel

SS304-1800-Sand Filter

Carbon Steel-1800-Sand Filter(No valve claw type)

Carbon Steel-2800-Sand Filter

SS304-2000-Sand Filter

SS304-3000-Sand Filter

Carbon Steel-2000-Sand Filter

Carbon Steel-2500-Sand Filter

Carbon Steel-2800-Sand Filter(Without valve)

Carbon Steel-3000-Sand Filter

Carbon Steel-3200-Sand Filter(No valve claw type)

Carbon Steel-3200-Sand Filter

Carbon Steel-3200-Sand Filter(without valve)

Carbon Steel-1200-Sand Filter(No valve claw type)

SS316-2200-Sand Filter

Sand Filter-Carbon Steel

SS304-2200-Sand Filter

SS304-800-Sand Filter

Carbon Steel-800-Sand Filter

SS304-1000-Sand Filter

Carbon Steel-1500-Sand Filter

SS304-1500-Sand Filter

Need Help?

If you need additional assistance with any product in this category, please contact our support team.