Plate-And-Frame Filter Press Manual

Table of Contents

Manual Overview

Manual Of Filter Press

Chapter 1: Announcements

The filter press bought is Hydraulic Filter Press. It is squeezed under the pressure of hydraulic station. To safely use JX Filtration filter press , please carefully read the following in advance, otherwise it will cause serious consequences.

![]() 1.1. Safety Instruction

1.1. Safety Instruction

1.1.1.Operators must be trained to operate the machine.

Operator must know the basic operation processes and daily maintenance of filter press to avoid harm caused to workers and our product.

![]() 1.1.2.Please do not disassemble the hydraulic system and electricity system without training.

1.1.2.Please do not disassemble the hydraulic system and electricity system without training.

Electricity of the hydraulic system and electricity control system has high voltage, please do not disassemble them without authorization.

![]() 1.1.3.Please pay much attention to rotatable parts to prevent injuries.

1.1.3.Please pay much attention to rotatable parts to prevent injuries.

Please do not touch any rotatable parts while working to avoid injuries.

1.1.4.Please wear related protective device

If your slurry is special, such as: toxic, volatile, inflammable etc, operators must wear protective devices. And please do not stand before the cylinder.

1.1.5.Safeties During Use

- As for the hydraulic station. All products do not include hydraulic oil. Here we recommend wear resistant 46# or 76# hydraulic oil. The quantity of oil needed:

| Model of Hydraulic Station | Quantity of Hydraulic Oil Needed |

| -------------------------- | -------------------------------- |

| 2.2 KW | 60 L |

| 4KW | 90L |

| 5.5KW | 150L |

| 7.5KW | 200L |

- The hydraulic oil should be changed after the first month use. Then change the oil every half year.

- Please pay much attention to the feeding pressure required. Plates are designed and recommended according to your needs, please install backflow pipe (please check 1.2.3.) to ensure the machine works under the required feeding pressure. Otherwise, the material will be ejected and plates will be damaged and might cause accident.

- The slurry before feeding into filter press should be even. Otherwise it could cause the thickness of cakes uneven, and might damage the plates.

- Please do NOT adjust the pressure meter on the hydraulic cylinder and the pressure-regulating valves on the hydraulic station personally or without permission. Otherwise, it will damage the cylinder or cause serious accident.

(2.2kw, 4.0kw, 5.5kw Hydraulic Station.)

- Specified number of plates must be placed in order and It's forbidden operating with less or more plates.

- Please ensure that plates (and frame) are in line and trim.

(Please refer to the red lines.) - Valves for filtered liquid, washing liquid and compressed air must operate according to the procedures and do NOT turn on at the same time.

- The slurry temperature must be controlled under 70℃, if it's beyond 70℃, please inform us in advance.

- While moving the plates, the force should be even and appropriate to avoid damage to plates and handles.

- After filtration every time, plates and cloths must wash clean. There should no residues on the surface, otherwise it might cause deformation.

- The filter cloth must meet requirements of slurry, otherwise, the filtrate will be not clear, or filtering speed will be too slow to get the best filtering effect.

- After a period of working, the filter cloth will be hard and their performance might decrease, so it's very necessary to conduct routine inspection. If clothes become hard, please neutralize, immerse and wash them using corresponding weak acid or alkali.

- The structure should be clean and the screw part should be lubricated with butter. The driving mechanism should keep smooth using lubrication oil. Please do not climb and strike the pipes connecting with inlet and outlet to avoid leakage at the joints.

- About related products:

Feeding Pump. The outlet pressure of feeding pump should match the required feeding pressure. Normally if the pressure is 0.1 mpa, correspondingly the head of pump should be 10 meters. For example, if the required feeding pressure is 0.6 mpa, correspondingly the head of pump should be 60 m.

The capacity pump is decided according to your needs, but a little more is recommended.

Note: In principle,we do not supply with pump.So please choose the right pump to be suitable with your slurry.

Water Pump. For membrane filter press, water pump will be used for secondary squeezing. Normally the pressure at outlet should be 0.8 mpa (Head: 80 m). (if use Air Compressor, the pressure at the outlet also should be 0.8 mpa.)

1.2.Installation

1.2.1.Lifting

While loading and unloading, please hoist the structure at the ends of two beams or using lifting lugs on the machine.

1.2.2. Foundation

1.2.2. Foundation

Every filter press produced by us will has a unique drawing for dimension and foundation. According to the drawing or real product, please build a concrete foundation. Then please put the machine horizontally on it. (Note: the feet at the end plate side should be fixed using screws or welding. The feet at the closing plate side do NOT be fixed and do ensure the beam is removable while filtering.) Additionally, there should be about 1 meter around the structure for worker's operation. The Filter press installation should be far away from corrosion, rain and sun.

1.2.3. Backflow Pipe

Please connect pipes as the following picture to control the feeding pressure.

Please strictly operate the filter press according to the following step.

- Close and squeeze plates after installation of filter cloths.

- Open valve 4, shutoff valve 3.

- Turn on the feeding pump.

- Observe the pressure by pressure meter 5.

- If the pressure is bigger than the required feeding pressure, please open return valve 3 slowly to release the pressure, so that the feeding pressure is stable and no more than the rated pressure.

- Finally the filtered liquid will be very little, then please turn off the feeding pump FIRSTLY.

- Please open plates SLOWLY, if the cake is not dry enough, plates also can be closed and continue to filter again.

- Secondary squeezing by compressed air or high pressure water. (This is for membrane filter press. If your filter press is not membrane filter press, please skip to next step.)

- Finally please discharge the cakes.

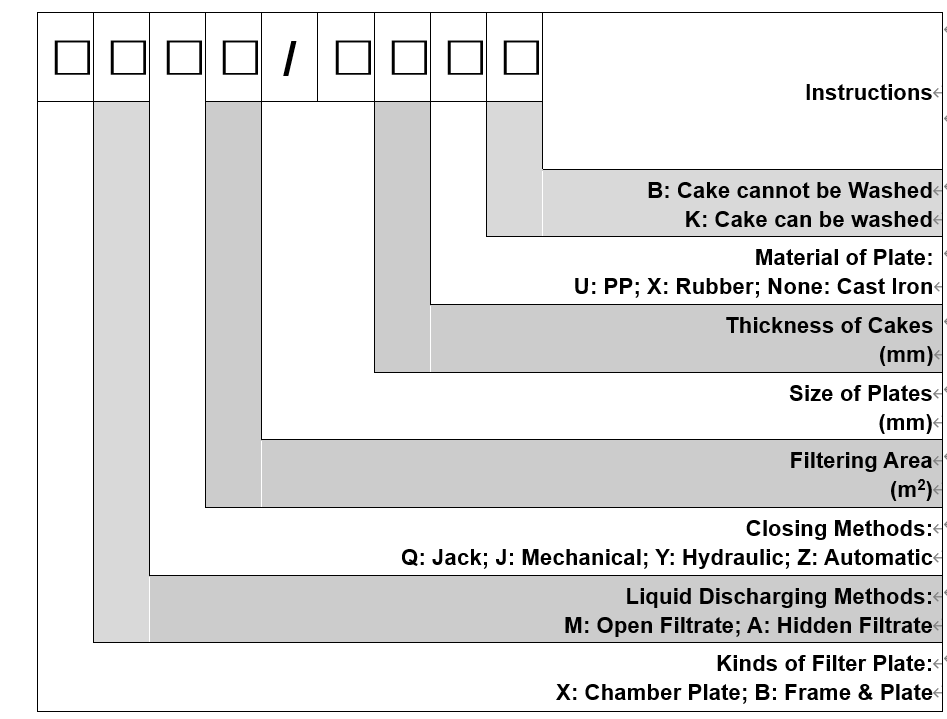

Chapter 2: Model Instructions

Chapter 3: Types Of Filter Press

Filter press can be divided into many types according to different ways:

3.1.According to various plates, filter presses generally include following types:

Plate Frame Filter Press, Chamber Filter Press, Membrane Filter Press and Recessed Filter Press.

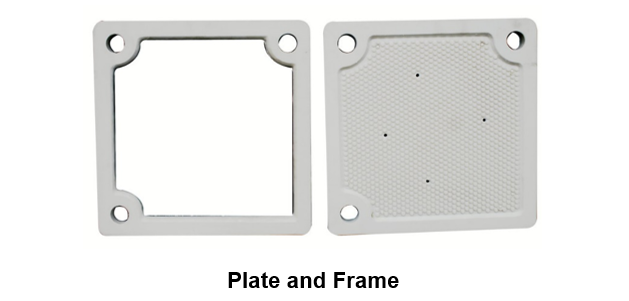

3.1.1.Plate Frame Filter Press.

The chamber is consist of plates and frames.

3.1.2.Chamber Filter Press

3.1.2.Chamber Filter Press

With the development of plate technology, pate and frame are now combing together and chamber filter press become popular, because chamber plates has the following advantages:

With the development of plate technology, pate and frame are now combing together and chamber filter press become popular, because chamber plates has the following advantages:

- Chamber plates can endure higher pressure.

- Convenient operation. Because of two-in-one design, half time of plate shifting can be saved.

- The feeding hole is in the center of the plate and the size is bigger, so blocking and bias pressure do not easily happen and can save a lot of filtering time.

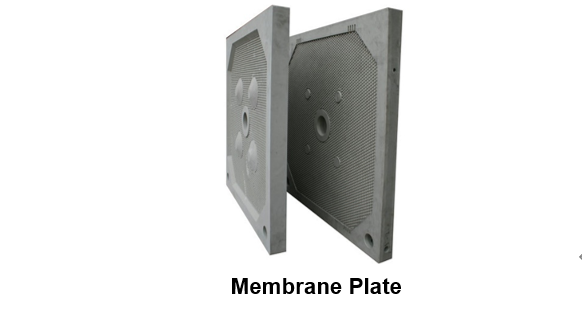

3.1.3.Membrane Filter Press

Membrane plates are “sandwich” design and hollow. When feeding is finished, the membrane plate can be blowed by compressed air or clean water, so that the final cake can be additionally squeezed to get the lower moisture.

Membrane plates are “sandwich” design and hollow. When feeding is finished, the membrane plate can be blowed by compressed air or clean water, so that the final cake can be additionally squeezed to get the lower moisture.

3.1.4.Recessed Filter Press

Recessed plate is use CGR design to perfectly avoid leakage, it's mainly used in some special slurry, such as: pharmaceuticals, rare metals, toxic, volatile, harmful, etc..

Recessed plate is use CGR design to perfectly avoid leakage, it's mainly used in some special slurry, such as: pharmaceuticals, rare metals, toxic, volatile, harmful, etc..

3.2.According to different closing methods, filter press can be divided into: Manual Jack Filter Press, Mechanical Filter Press and Hydraulic Filter Press. Manual Jack Filter Press is features of easy structure, easy operation. Normally it's used for filtering area 1-40 m2. Mechanical Filter Press is suitable for 10-100 m2. Hydraulic Filter Press is mainly for 4-500 m2 or much bigger.

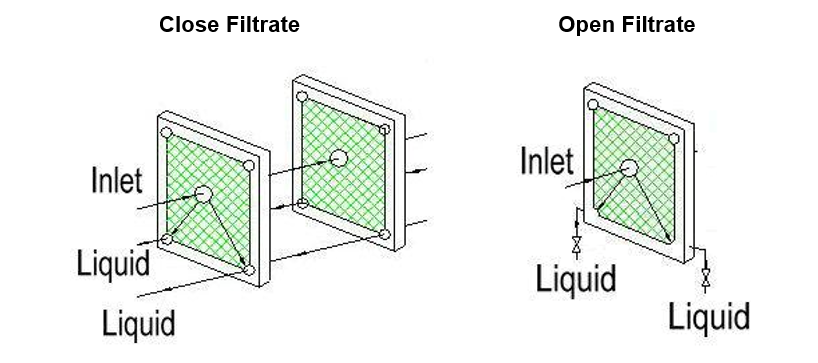

3.3.According to the liquid discharging methods, filter press is divided into open filtrate and close/hidden filtrate.

Close filtrate: filtered liquid is discharged via the pipe, which is consisted of outlet of all plates. It is mainly used for special slurries, such as: toxic, volatile etc..

Close filtrate: filtered liquid is discharged via the pipe, which is consisted of outlet of all plates. It is mainly used for special slurries, such as: toxic, volatile etc..

Open filtrate (Recommended): filtered liquid is discharged via the outlet on the every plate. Open filtrate is widely used, because if the filter cloth is damaged, it can directly find the problem soon. (If the filter cloth is broken, the liquid will be not clean. Please turn off the tap and repair the cloth after discharging.)

3.4.According to the final cake whether needs washing, filter press is divided into cake washable filter press and cake no wash filter press.

3.5.Additionally according to customer's individual requirements, we could manufacture special filter press: Carton Iron Filter Press, Stainless Steel Press, High Temperature Filter Press, High Pressure Filter Press etc., to satisfy customer's various needs.

Chapter 4: How to Use

After the filter press is lifted on the foundation and before operation, please check the followings:

- Please confirm the Backflow Pipe has been installed. (Please refer 1.2.3.)

- The holes on the clothes match plates.

- The feeding hole on the plates and the holes on the cloth must be concentric.

- After closing the plates, there is no impurities between two squeezing surface (Such as: cloth ties etc.). And the filter cloth must be flat, no wrinkle and ensure no damage.

- Number of plates (and frame) are right and match the model.

- The cloth press on the end plate has tightly pressed the filter cloth.

4.1.Preparation

4.1.Preparation

4.1.1.Installation of taps.

This step is only for open filtrate. If your plates belong to hidden filtrate, please skip to next step.

4.1.2.Installation of filter cloth.

Chamber Plates:

Please install the filter cloth according to the following steps:

Plate Frame Plates:

Notice:

Finally the filter cloth between two squeezing surfaces of plates should be: flat and no impurities (such as the belts on the filter cloth etc.).

4.2. Installation of electrical wires

Notice: Please ensure the power is 3 phase 4 wires, and the voltage, frequency match your power.

4.2.1. Installation of External Power

Please connect the external power with the terminal blocks according to following steps:

| Terminal Blocks | External Power |

| --------------- | -------------- |

| N | Null/Zero Line |

| A | Live Line |

| B | Live Line |

| C | Live Line |

4.2.2. Installation of motor of hydraulic station

Please connect the motor of hydraulic station with the terminal blocks according to following steps:

| Terminal Blocks | External Power |

| --------------- | -------------- |

| U | Live Line |

| V | Live Line |

| W | Live Line |

NOTE: Please ensure the fan on the motor run CLOCKWISE. If do not run clockwise, please exchange any both of them.

4.2.3.Installation of Pressure Meter (Please check the circuit diagram.)

Please connect the Pressure Meter according to following steps:

| Terminal Blocks | Function | Color |

| --------------- | -------- | ----- |

| 004 | Upper Limit | Red |

| 005 | Lower Limit | Blue |

| | Zero | Multicolor (Yellow & Green) |

Briefly, the wire color of the meter should match the color of our wire.

Note:Normally before delivery, limit of pressure meter has be set. Please do not adjust without permission. (15 mpa: low limit; 18 mpa:upper limit) OR (17 mpa: low limit; 20 mpa:upper limit).

And please set the high pressure limit first.

4.2.4.Installation of Magnetic Valves (Please check the circuit diagram.)

Note: For every magnetic valve just has two wires, one is for null/zero line, one is for live line. Please do NOT connect the both with two live wires!

| Terminal Blocks | Function | Color |

| --------------- | -------- | ----- |

| 303 | Closing/Squeezing | Red |

| 302 | Open/Release | Blue |

| 4 | Null/Zero Live | Multicolor (Yellow & Green) |

4.2.5.Installation of Oil Hose

Please install oil hoses according to the labels. The high pressure oil hose is connecting with the head of cylinder and the low pressure oil hose is connecting with the the back of cylinder.

Note:

- The high pressure oil hose is connecting with the port on the head of the cylinder. The other one is for gas discharging.

- The low pressure oil hose is connecting with the port on the back part of the cylinder. The other one is for gas discharging.

- For the first use, while squeezing plates, the cylinder might not go smoothly. The situation is normal, because there has air in the cylinder. Please loosen the gas port lightly to discharge the air.

- Oil hose for high pressure and lower pressure must not connect inversely. It might cause accident.

4.2.6.Installation of Travel Limit Switch

Cylinder travel Limit Swith is used for protecting the hydraulic cylinder. It’s under the beam. Please connect the both wires on the switch to the terminal 11 and 13 in the cabinet.

| Terminal Blocks | Function | Color |

| --------------- | -------- | ----- |

| 006 | Cylinder Travel Limit | |

4.3.Operation Procedures

After connecting wires, please strictly operate our filter press by following steps:

- Press “Close” button to squeeze the plates.

When the pressure arrive the upper limit of the pressure meter, it will automatically stop; if the pressure is lower than the lower pressure set, the hydraulic station will increase pressure automatically. - If the filtrate flow is very very slow and small, that means the filtering process has finished, please turn off the feeding pump firstly.

- Then please turn on the high pressure water pump or air compressor to realize the secondary squeezing. (This is for membrane filter press. If not please skip to next stop.)

- Please release the pressure of the high pressure water or compressed air. (This is for membrane filter press.If not please skip to next stop.)

- Then please press the “Open” button to pull back the closing plate SLOWLY. (If the cake is not dry enough, plates could be closed again and continue to feed slurry.)

- When cylinder is fully back, please press “Stop” button to end the movement.

- Discharge cake manually.

- Clean filter cloth and plates.

Note:

- Please turn off the feeding pump firstly before discharging.

- Before change any movement/action, please press related “Stop” button first.

- For membrane filter press, the water pump or air compressor must turned off and ensure there is NO squeezing pressure in membrane plates before discharging. (This is for membrane filter press. If not please skip to next stop.)

Chapter 5: About Filtration

- The filtration effect will be various according to the slurry's condition, such as: solid performance, solid content, temperature, ph value, particle size etc.. And some slurries need add chemical powders to regulate the slurry's filtering performance, such as filtration aid, flocculant etc., so the final cake will be different.

- At beginning of filtering, the filtered liquid will be not very clean, because the precoat is not formed. Please continue and it will be cleaner after a while.

- Little leakage is reasonable, because of cloth capillarity/wicking. If big leakage happens, please increase some closing pressure (a little).

- Please observe the filtered liquid, if suddenly filtrate is muddy, please close the tap. (For hidden filtrate filter press, please stop the machine.) Then check the clothes.

- If the pressure is higher and the liquid flow is very small, the filtration is finished.

- If the filtering time is too long or the cakes can not be formed, please try to lower the liquid content, such as: increase precipitation time; use thickener; add filtration aid and flocculant etc..

- If cakes need washing, please close the taps on the washing plates and feeding valve, then fill in the water to wash cakes. The water pressure should not over the rated pressure. The washing time is decided by the filtering effect.

- To realize better dewatering effect, the cakes can be blowed by compressed air and the method is same as the above. The compressed air also can be fed in via feeding hole. Or use our membrane filter press directly.

Chapter 6: Troubleshooting

| Faults | Possible Reasons | Solving Methods |

| ------ | ---------------- | --------------- |

| Hydraulic system has serious noise or pressure is not stable. | There is no oil in the tank or oil pipe is blocked. | Add oil, clean the oil pipes. |

| There has air in the oil pipes | Discharge the air. |

| The pump is damaged | Replace or repair. |

| Relief valve can not work stably. | Replace or repair. |

| Oil pipe shakes. | Fix them. |

| The closing pressure is not enough or even no pressure. | The oil pump is damaged. | Replace or repair. |

| The pressure adjustment is not enough. | Adjust it slowly. |

| Oil viscosity is low. | Change the oil. |

| Oil leakage | Repair |

| While squeezing plates, the pressure is not enough. | The high pressure relief valve is blocked or damaged. | Replace or repair. |

| Reversing valve is damaged. | Replace or repair. |

| The seal of the big piston is broken. | Replace |

| "O" seal of small piston is damaged. | Replace |

| The oil pump is damaged. | Replace or repair. |

| The pressure is not adjusted rightly. | Regulate it agin. |

| While cylinder is open, the pressure is not enough. | The low pressure relief valve is blocked or damaged. | Replace or repair. |

| The seal of small piston is damaged. | Replace |

| The "O" seal of small piston is damaged. | Replace |

| The piston crawls. | The oil circuit has air. | Discharge air |

| Serious leakage between plates. | Deformation of plates and frames | Replace |

| There are impurities on the sealing surface. | Clean |

| Clothes are not flat or has wrinkle. | Replace or flat them. |

| Closing pressure is not enough. | Increase the closing pressure. |

| Deformation or breakage of plates or frames. | The feeding pressure is too high. | Decrease the pressure. |

| The temperature of slurry is too high. | Decrease the temperature |

| The closing pressure is too high. | Adjust the closing pressure rightly. |

| The filtering speed is too fast. | Slow down the filtering speed. |

| The inlet is blocked. | Clean the inlet. |

| The machine stops during working. | Do not stop during working. |

| Suddenly stop while filtering. | Do not stop while filtering. |

| Often pressure complement | One-way valve is not good closed | Washing using clean diesel or Replace |

| Cylinder has leakage. | Replace the seal |

| Direction valves can not work. | Valve plug is blocked or damaged. | Clean or replace it. |

| Plate shifter can not be pulled back. | The pressure of oil motor is low. | Regulate it. |

| The pressure of pressure relay is low. | Regulate it |

| Beams bend. | The foundation is not firm and flat. | Repair or rebuilt. |

| Feet do not go or back synchronously | The closing force is not even. | Open plates and ensure the plates are in line, then close again. |

This section provides comprehensive documentation for all products in the Plate-And-Frame Filter Press category. Please select a specific product below to view its detailed manual.

Available Products

SS316-630-Plate Press Filter

450(10)-Plate Press Filter

520(6)-Plate Press Filter

SS304-630(10)-Plate Press Filter

Need Help?

If you need additional assistance with any product in this category, please contact our support team.