Tubular Filter Manual

Table of Contents

Manual Overview

Tubular Filter Operation Manual

The tubular filter is particularly suitable for liquid filtration applications with high flow rates and high filtration accuracy requirements, especially when the liquid contains fibers or colloidal impurities.

Typical application media include:

- Pulp & Paper Industry: white water reuse, process water, spray water, clear white water, ultra-clear white water

- Petrochemical Industry: circulating water, condensate water, cooling water, diesel, gasoline, naphtha, FCC slurry oil, AGO (atmospheric gas oil), CGO (coking gas oil), VGO (vacuum gas oil)

- Others: water used in non-woven material processes, circulating water, etc.

Operation and Maintenance Guide

I. Pre-Start Checks

- Safety check: Ensure that the power supply and air supply to the system have been completely switched off. Check that all pipeline connections are correct and secure, and make sure no tools or foreign objects remain near the equipment.

- Installation confirmation: Confirm that the equipment is installed downstream of the pump according to the design requirements, and that the inlet pressure meets the minimum requirement of > 0.3 MPa.

- Instrumentation check: Confirm that the inlet and outlet pressure gauges and differential pressure transmitter are correctly installed and reading zero. Check that controller power wiring is correct.

- Utilities confirmation: Ensure that the compressed air supply pipeline is correctly connected, with pressure stable within the required range (typically 0.4–0.7 MPa).

- Valve status confirmation: Manually check whether the main pipeline valves (inlet valve, outlet valve, drain valve) can open and close normally, and place them in the correct pre-start position (typically inlet valve closed, drain valve closed).

II. Commissioning and Operation

- Initial Start-up

- Slightly open the inlet valve to allow the liquid to slowly fill the filter and discharge air from the housing.

- Observe pressure gauge readings and pipeline connections to confirm that there are no leaks.

- Slowly open the outlet valve and gradually increase pressure to normal operating conditions.

- Parameter Settings

- Use the controller panel to enter the parameter setting menu.

- Differential pressure start value: Set the backwashing trigger differential pressure according to process requirements. The recommended initial setting is 0.05 MPa, adjustable based on actual filtration performance and backwash frequency.

- Time start value: Set the maximum time interval for backwashing as backup control to differential pressure, e.g., 2–8 hours.

- Set the backwash duration for each filter element, typically 20–60 seconds, to ensure thorough cleaning.

- Manual Test

- Select “Manual” or “Test” mode on the controller.

- Start the backwashing program of each filtering unit sequentially, observing whether the drain valve opens and closes normally and whether the backwash flow is smooth and strong.

- Check whether the system pressure remains stable during backwashing.

- Automatic Operation

- After manual testing is verified to be normal, switch the system to Automatic mode.

- The equipment will automatically and sequentially backwash each filtration unit based on the set differential pressure or time, achieving continuous, uninterrupted filtration.

III. Routine Maintenance and Care

- Daily Inspection

- Observe and record inlet/outlet pressures and differential pressure values.

- Check whether any alarm messages appear on the controller panel.

- Listen for abnormal noise or vibration and check for leaks.

- Weekly/Monthly Inspection

- Check the compressed air filter-regulator, draining accumulated water and impurities.

- Inspect pneumatic drain valve cylinders and connections for looseness or damage.

- Periodic Maintenance (every 6 months or as required)

- Filter element inspection and cleaning: Shut down the system, depressurize, open the housing, and remove the filter elements.

- Clean using low-pressure water from inside to outside, or lightly brush with a soft brush. Do not scrape with hard tools to avoid damaging the wedge wire surface.

- Inspect for deformation, damage, or severe clogging; replace if necessary.

- Sealing inspection: Check sealing rings and gaskets at all flange connections. Replace immediately if aging, deformation, or damage is found.

- Long-term Shutdown

- Completely drain liquid from the equipment.

- Thoroughly clean and dry all filter elements.

- Close all valves and disconnect power and air supply.

IV. Precautions

- Safety first: Before any maintenance work, ensure that the system is fully depressurized and power and air supplies are disconnected. Hang “Do Not Operate” warning tags.

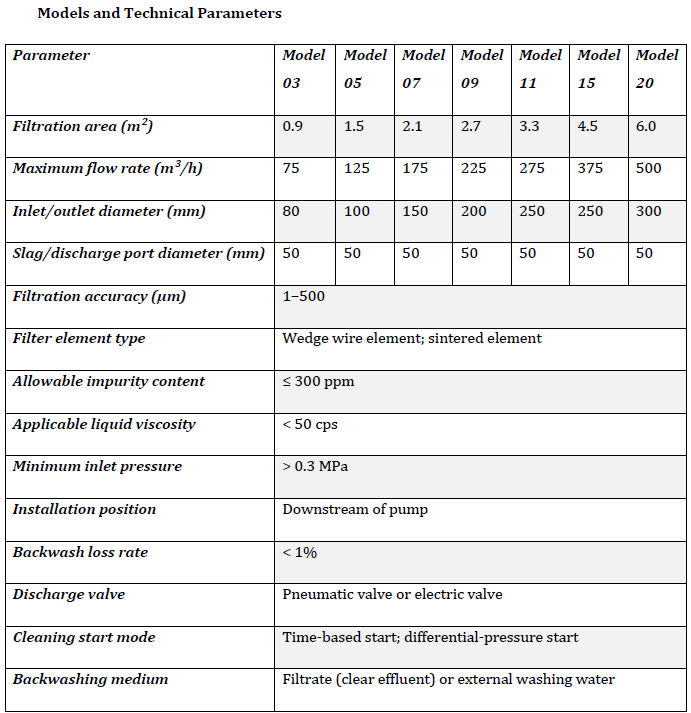

- Liquid properties: Ensure the liquid viscosity is < 50 cps and impurity concentration ≤ 300 ppm. Exceeding these values may seriously affect filtration and backwashing performance and even damage the equipment.

- Winter protection: For outdoor installations, drain the equipment and pipelines during cold-weather shutdowns to prevent freezing damage.

- Professional service: If encountering unresolved faults (continuous controller alarms, abnormal valve actions, etc.), stop operation immediately and contact professional service personnel.

This section provides comprehensive documentation for all products in the Tubular Filter category. Please select a specific product below to view its detailed manual.

Available Products

SS304-12-Tubular Filter

Model: JX-FHL-12-SS304

Price: $18255

SS2507-16-Tubular Filter

Model: JX-FHL-18-SS2507

Price: $57140

SS304-Modular Self-cleaning Filter

Model: JX-FHL-1-SS304

Price: $3110

SS316-16-Tubular Filter

Model: JX-FHL-18

Price: $36808

SS316-3-Tubular Filter

Model: JX-FHL-3-SS316

Price: $9905

SS304-8-Tubular Filter

Model: JX-FHL-8

Price: $13950

SS304-4-Tubular Filter

Model: JX-FHL-4

Price: $10160

SS304-3-Tubular Filter

Model: JX-FHL-3-SS304

Price: $7620

SS304-6-Tubular Filter

Model: JX-FHL-6

Price: $11905

SS304-16-Tubular Filter

Model: JX-FHL-16

Price: $23490

SS316-Modular Self-cleaning Filter

Model: JX-FHL-1

Price: $4450

Need Help?

If you need additional assistance with any product in this category, please contact our support team.

Mobile / WA / WeChat: +86 159 2865 0174

Teams / Email: sales@filtrationchina.com